Intelliweld®

More than a Control System

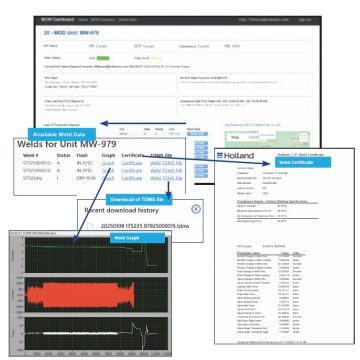

Holland’s Intelliweld Control System was designed by people who weld rail for people who weld rail. For over a decade our fleet of nearly 200 MobileWelders in North America and Australia have been using the Intelliweld system to provide an unmatched degree of accuracy and > 99.99% weld quality conformance.

Intelliweld provides unparalleled control over the flashing process and rail consumption. Simple program adjustments allow us to tailor rail consumption to requirements for localized track structures and target rail neutral temperature. Qualified weld programs are password-protected to prevent unintended changes. In addition, lower rail consumption reduces the amount of de-clipping and clipping required.

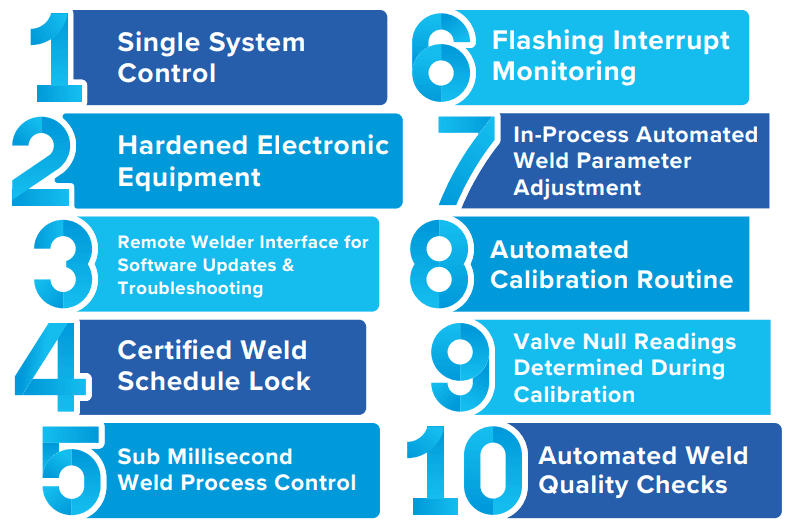

Top 10 features